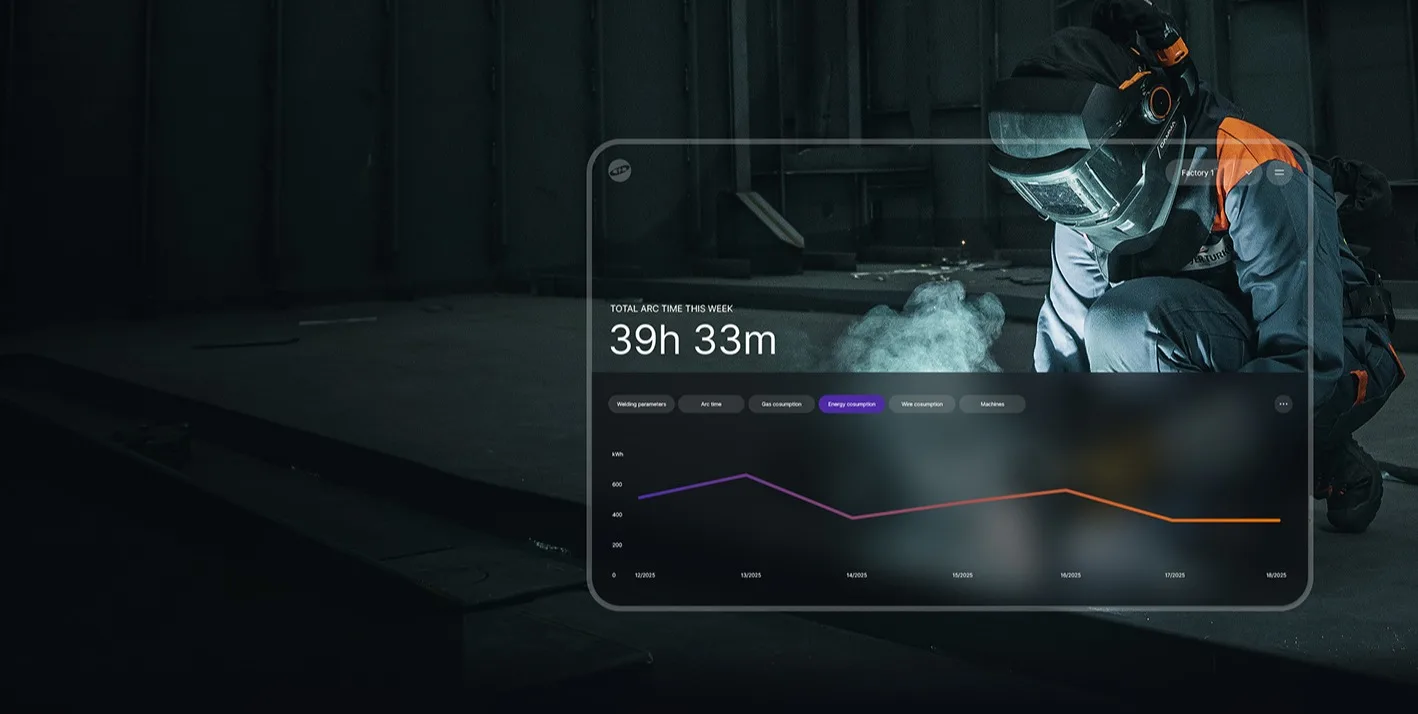

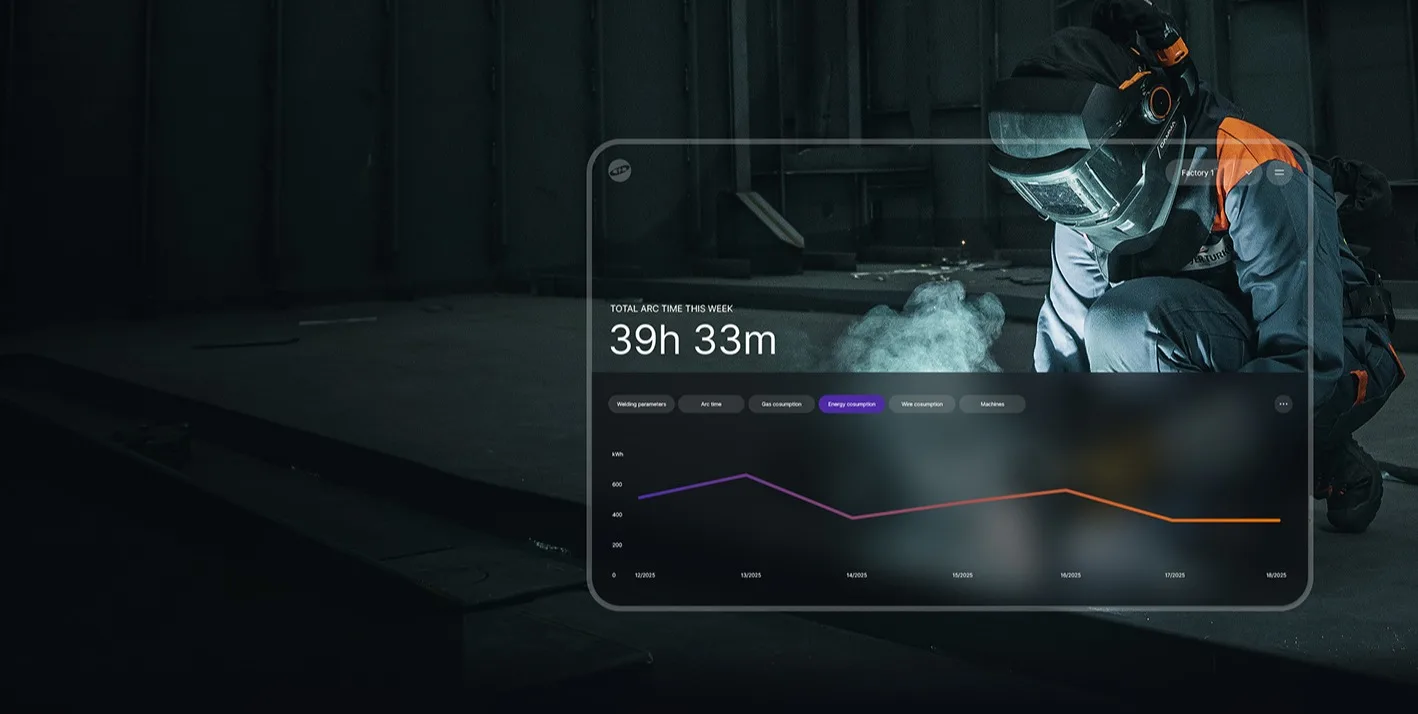

Streamline your welding operations

WeldEye is a cloud-based software to manage welding production.

WeldEye software solutions for welding management

WeldEye is a universal solution for managing welding production. It fits any size and type of organization that performs welding within the requirements of international welding standards like ISO, ASME, and AWS. WeldEye provides control in all processes - including welding procedures, welder and inspector qualifications, documentation, reporting and administration. Most importantly, you get 100% traceability to any weld you ever make.

Take full advantage of digital welding production management and its benefits. WeldEye's modular software structure is based on several useful functions that serve the needs of welding-related industries.

Explore our welding management solutions

WeldEye ensures comprehensive welding data management

Welding traceability is becoming an increasingly essential requirement in industries where safety, quality, and compliance are paramount. WeldEye is a cloud-based welding management software designed to eliminate manual documentation errors and streamline traceability. It automatically collects and stores critical welding data, ensuring compliance with industry standards.

WeldEye ensures comprehensive welding data management

Welding traceability is becoming an increasingly essential requirement in industries where safety, quality, and compliance are paramount. WeldEye is a cloud-based welding management software designed to eliminate manual documentation errors and streamline traceability. It automatically collects and stores critical welding data, ensuring compliance with industry standards.

Manage welding heat input with WeldEye

Companies using WeldEye have seen significant improvements in traceability, quality control, and cost efficiency. Heat input is a critical factor in welding quality across industries. Deviations in heat input can lead to grain growth, cracking, residual stresses, distortion, or weak weld joints, which can compromise safety, quality, and efficiency. WeldEye continuously records and analyzes heat input, enabling compliance with welding regulations, early detection of process inconsistencies, reduced rework and higher overall efficiency.

Manage welding heat input with WeldEye

Companies using WeldEye have seen significant improvements in traceability, quality control, and cost efficiency. Heat input is a critical factor in welding quality across industries. Deviations in heat input can lead to grain growth, cracking, residual stresses, distortion, or weak weld joints, which can compromise safety, quality, and efficiency. WeldEye continuously records and analyzes heat input, enabling compliance with welding regulations, early detection of process inconsistencies, reduced rework and higher overall efficiency.

What our customers are saying

Latest news

We proudly welcome Dutch maritime giant Royal IHC to WeldEye family

It’s a real pleasure to welcome Dutch maritime technology mammoth, Royal IHC to the WeldEye family.

Read moreExtending a warm WeldEye welcome to Murphy

WeldEye and Kemppi UK are very pleased to be able to welcome Murphy as a new customer.

Read moreWeldEye and Griffin Marine Services: Embracing Digitalisation

WeldEye is excited to welcome Griffin Marine Services to the WeldEye and Kemppi Australia family.

Read moreNew WeldEye Fleet Management – a big picture

Kemppi has launched WeldEye Fleet Management, a new module for the universal WeldEye software.

Read moreWeldEye ArcVision – view your basics, tackle your challenges

WeldEye has expanded its universal software offering by introducing a brand-new module; WeldEye ArcVision. It offers reliable, accurate and real-time data on:

Read moreCan you afford to ignore the value of welding knowledge?

Read our white paper on the demonstrated value potential that the introduction of a

welding management software provides on all stages of the welding process.